Welcome to HYNOLOGY

Booster of the energy transition, using Hydrogen technologies

Technologies

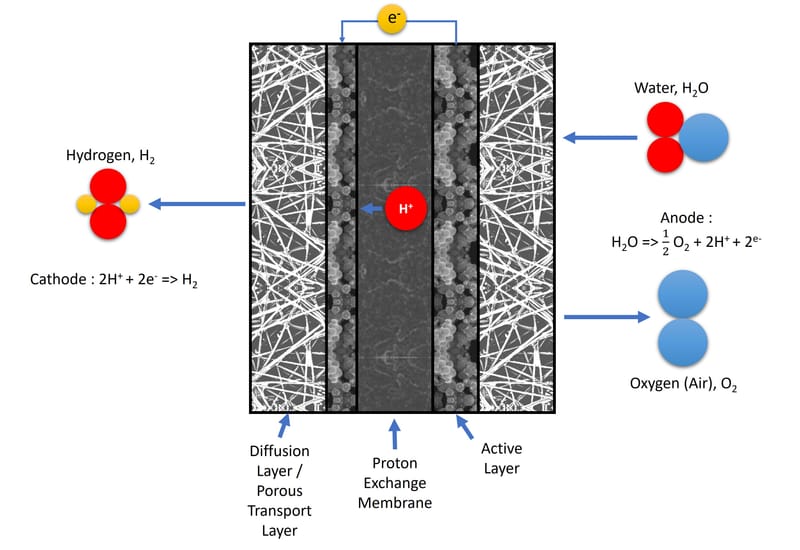

PEM electrolysis

PEM electrolysis is an advanced hydrogen production method that leverages proton exchange membrane (PEM) technology and has rapidly changed the hydrogen production landscape. This process separates water into its two primary elements: hydrogen and oxygen. The heart of this system consists of an anode (positive electrode) and a cathode (negative electrode) separated by a proton-conducting membrane. The anode oxidizes water molecules and separates them into hydrogen ions (H+) and dioxygen (02). Hydrogen ions, or protons, pass through the membrane to the cathode where they are reduced to produce hydrogen gas. The PEM electrolysis process shines in its efficiency, operating at extremely high energy efficiencies, often outperforming traditional electrolysis techniques.

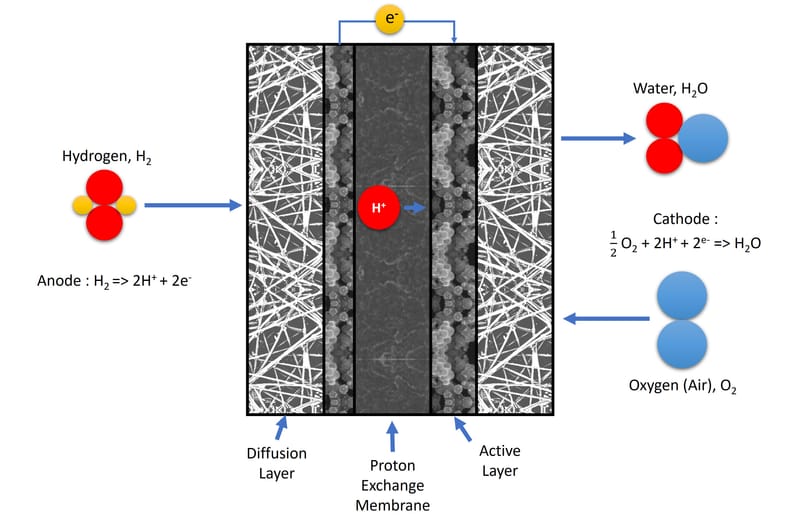

PEM fuel cell

PEM fuel cell technology is an energy solution that redefines the way we harness energy. Using the principle of the proton exchange membrane (PEM), this cutting-edge technology exploits chemical reactions between oxygen and hydrogen to directly generate electrical energy. Unlike traditional energy sources, PEM fuel cell technology is highly efficient, environmentally friendly and emits only water, making it an exceptional choice for applications ranging from heavy mobility applications (land, sea or aeronautics) up to individual or centralized stationary generators.

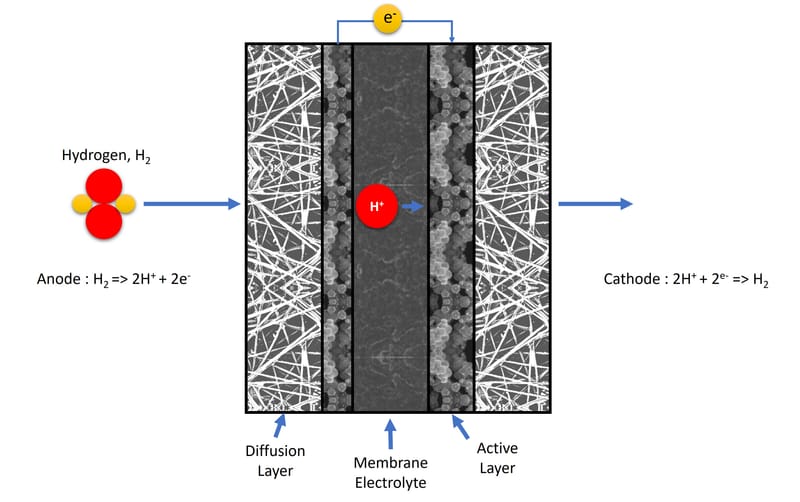

Electrochemical compression

Electrochemical hydrogen compression is a technology aimed at reducing the physical space occupied by hydrogen, in order to ensure efficient storage and transport. This technology uses electrochemical processes to generate hydrogen under pressure, thereby compressing it to a fraction of its original volume. This achieves higher energy density, making this innovative solution ideal for hydrogen fuel cell applications, particularly in the transportation and renewable energy sectors. The service promises high compression efficiency, minimal energy loss and, most importantly, it eliminates the need for mechanical compressors which often result in increased costs and maintenance requirements.

Products and Services

Materials

HYNOLOGY develops and produces electrochemical components for hydrogen-related technologies: electrolyser, fuel cell and electrochemical compressor. An industrial production line is currently being designed/built.

Learn MoreResearch and development

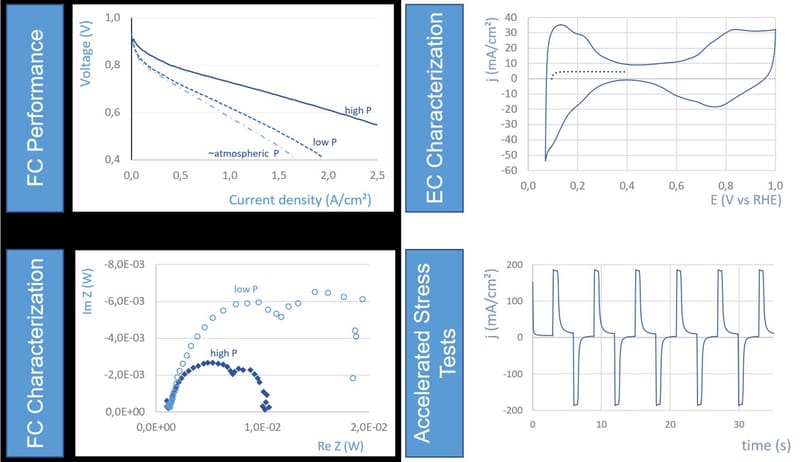

HYNOLOGY offers Research and Development services according to specifications in the field of electrochemical components for hydrogen-related technologies. These services include the formulation of catalytic inks for electrochemical devices, their deposition following several processes, the complexing of these components with various materials, and their electrochemical characterization on dedicated test benches.

Learn MoreMaterial/Equipment

HYNOLOGY offers a range of test materials or equipment specially designed for the characterization of electrochemical components.

Learn MoreMaterials

Research & Development

Electrochemical characterization of components

HYNOLOGY offers R&D services for testing and electrochemical characterization of components intended for integration into fuel cell, electrolysis or electrochemical compression applications.

Formulation of catalytic inks

Whatever the applications or technologies studied, HYNOLOGY supports you in the formulation of catalytic inks from commercial or specially synthesized catalysts and/or from proton or anionic ionomers.

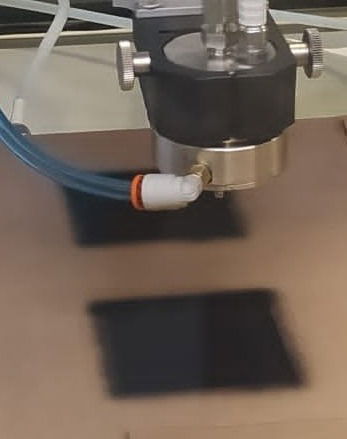

Active layers coating

Using innovative or commercial catalytic inks, the HYNOLOGY teams study the direct or indirect processes most suited to the targeted supports to obtain efficient and durable deposits. These studies include machine configuration, ink rheology, and deposit characterization.

Material/Equipment

File manager

2024-04 Press Release

We're proud to announce that we've been selected, together with our partner Hycco, as winners of the Ademe's "Technological bricks and hydrogen demonstrators" call for projects, with funding of 3.34 million euros for our NeGerHy project! This collaborative project aims to qualify two essential fuel cell components: the Membrane Electrode Assembly (MEA) for Hynology and the Bipolar Plates (BP) for Hycco. This partnership represents a significant step forward in the French hydrogen landscape: France's only two manufacturers of fundamental fuel cells components (AME + PB = 92% of production costs) are coordinating to supply technologies: 1/ perfectly interfaced with each other

2024-04 Press Release

ADEME Project “Technological Bricks and Hydrogen Demonstrator”

HYNOLOGY Flyer

Genesis of the company

Launched in May 2022, HYNOLOGY is based in the Grenoble area, and will manufacture the active components for fuel cells for heavy mobility, and for the production of green hydrogen by electrolysis. This project is based on the observation that, since the end of the last decade, hydrogen technology applications (fuel cells and electrolyzers) have shifted from the passenger car market to the heavy mobility and green hydrogen production markets, with a radical change in component characteristics. Product lifespan had to be multiplied by 5, becoming more important than cost or performance. What's more, global supply was no longer in line with the needs of the new applications, either in terms of quantity (very inadequate production capacity) or quality (mismatch between the products on offer and the real need). The project therefore involves setting up a production plant for electrochemical components for fuel cells and electrolyzers in the Grenoble area before 2030. Laboratory production began in early 2023 to meet the demands of the first customers, pending installation of the first pilot line, scheduled for completion before 2026.

Chronology

Creation of HYNOLOGY

Filing of the statutes of the company HYNOLOGY on May 18, 2022, and start of strategic and technological studies.

18/05/2022First fundraising

First fund-raising (Business Angels and "Love Money") to invest in R&D equipment to meet initial demand

28/07/2022“Explore H2” winner

HYNOLOGY is part of SAFRAN's "Explore H2" program intended for start-ups with strong potential in the hydrogen sector for aeronautics.

01/10/2022R&D Lab validated

The equipment ordered following the first fundraising in July 2022 is installed and validated. the first concrete studies can begin.

15/02/2023First order completed

First order of electrochemical components (MEAs) produced and shipped.

01/03/2023Client portfolio > 10

After 15 months of activity, HYNOLOGY has already delivered orders to more than 10 customers in France and abroad.

01/08/2023First patent filed

First patent filed protecting the innovative active layer deposition process for fuel cells and electrolyzers.

15/12/2023Team

Renaut MOSDALE

Founder - President

Guillaume BRAESCH

Electrochemical characterization manager

Annette MOSDALE

Catalytic inks manager - Formulation and coating

Charlotte VIFFRAY

Technicienne R&D - Spécialisée dans les dépôts d'encres

Contact

- 32 Rue de Comboire building F1, 38130 Échirolles, France